Functionalisation of composite profiles

in cooperation with

Together with our partners from INOMETA GmbH and Mitsui Chemicals Europe GmbH as well as the Institute of Lightweight Engineering and Polymer Technology we have rethought the functionalisation of high-performance profiles.

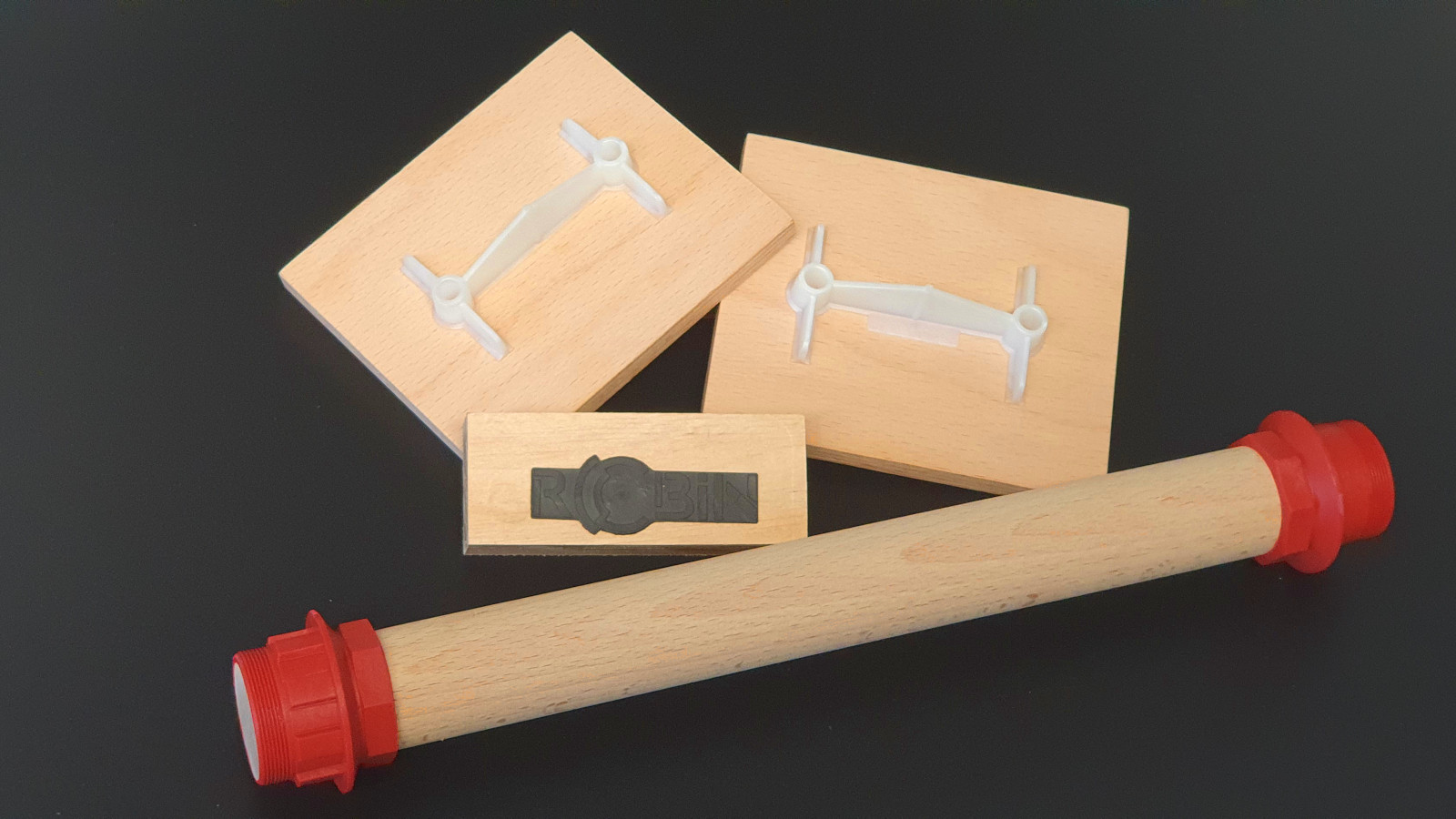

The high-performance tapes TAFNEX® were processed into composite profiles by Mitsui in laser-based thermoplastic winding at INOMETA before they were then functionalised with #ROBIN. Polypropylene was used here as the material base. A generic pipe demonstrator with splined shaft, sliding surface and thread was implemented. We were thus able to successfully demonstrate the high design and functional diversity of this process chain.

More information can be found in the pictures, the process video or the various technical articles: