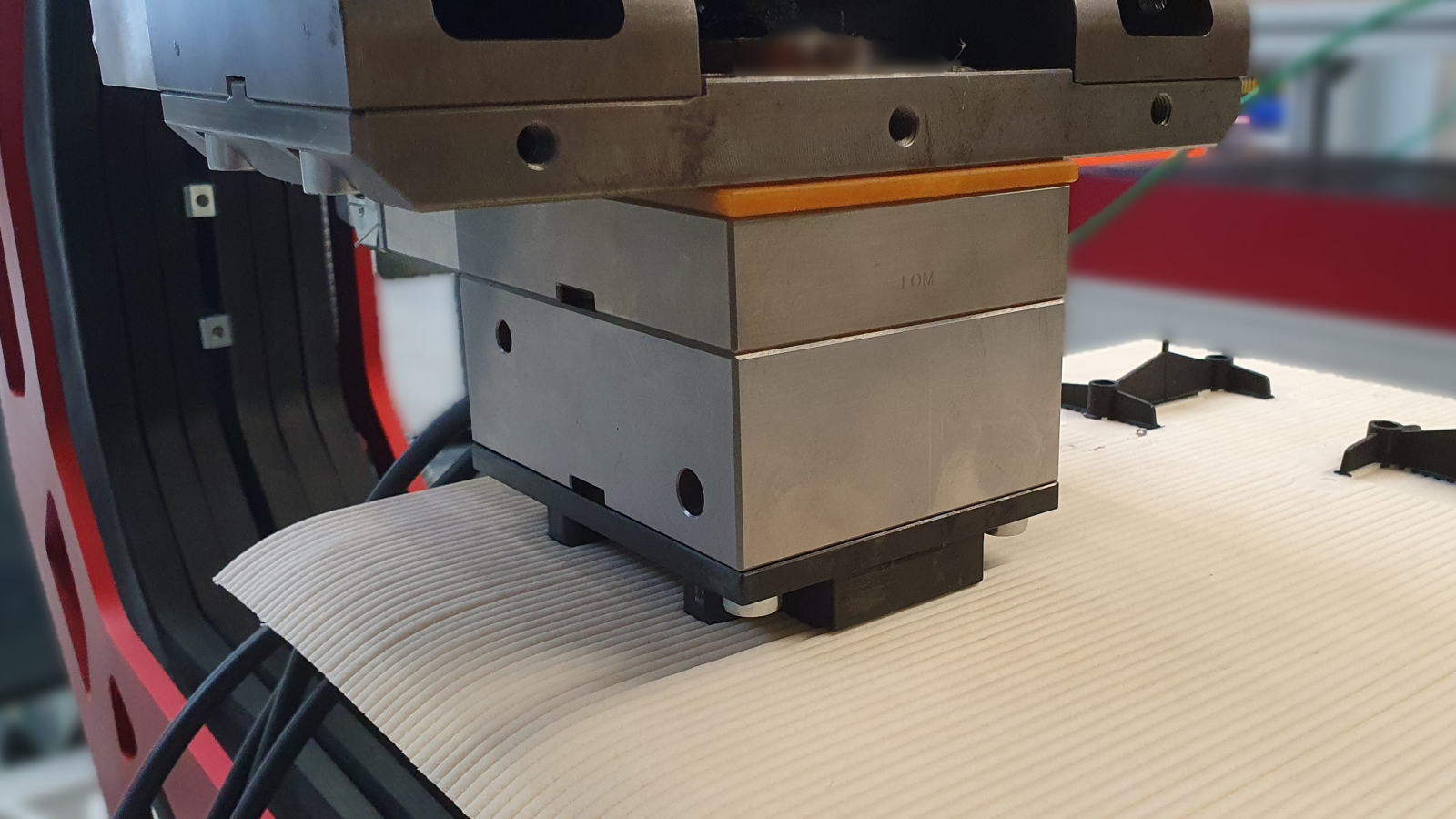

Application.

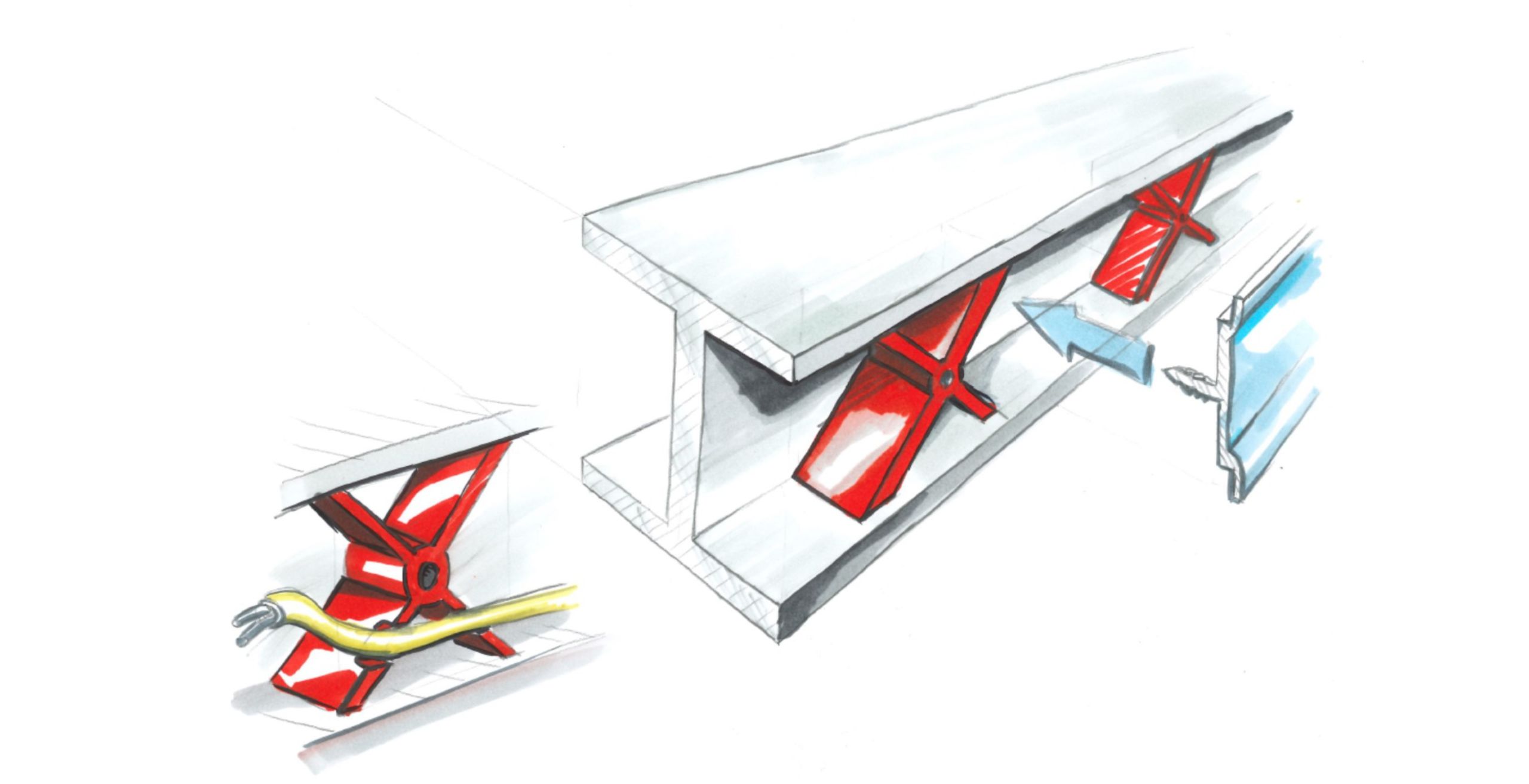

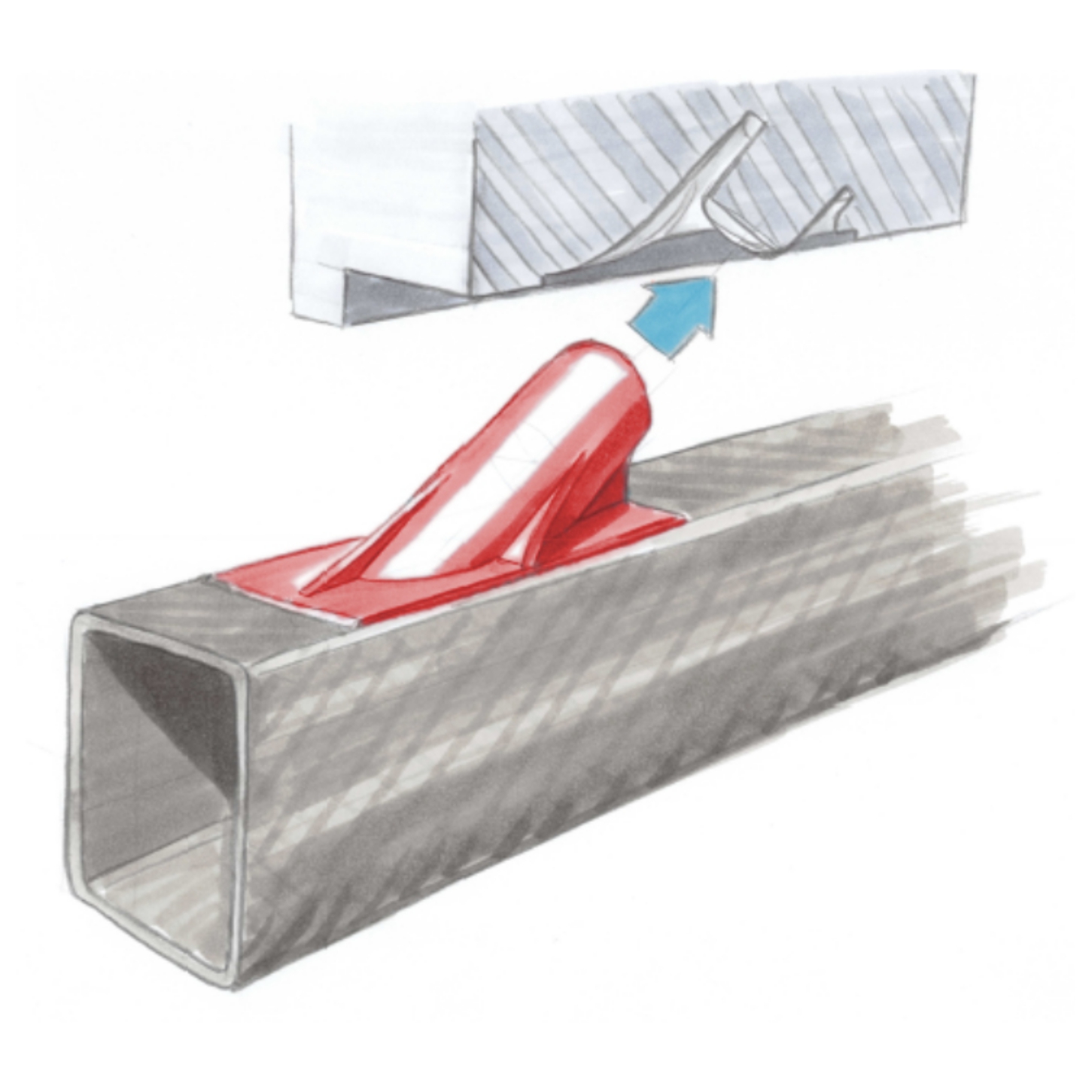

Versatility in hybrid component design.

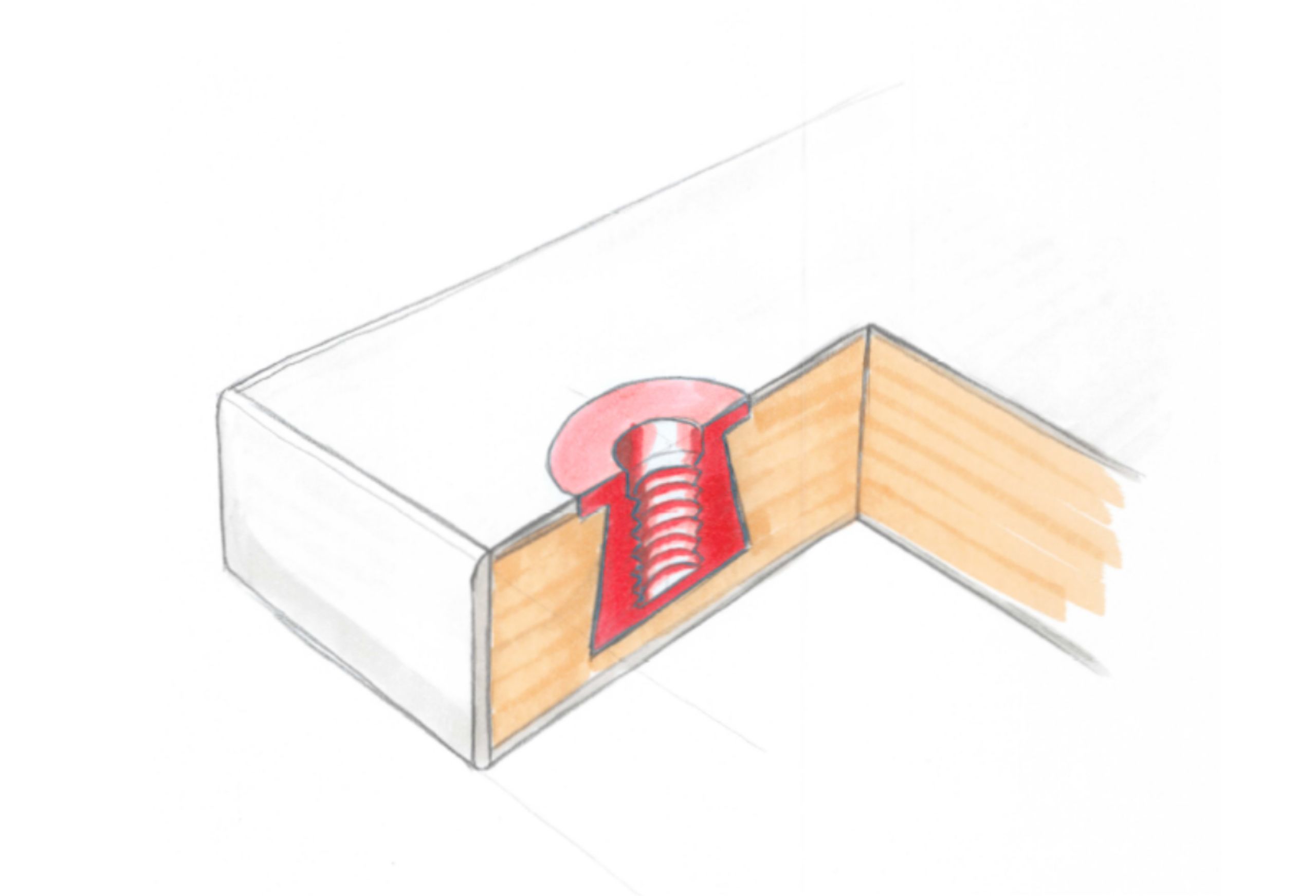

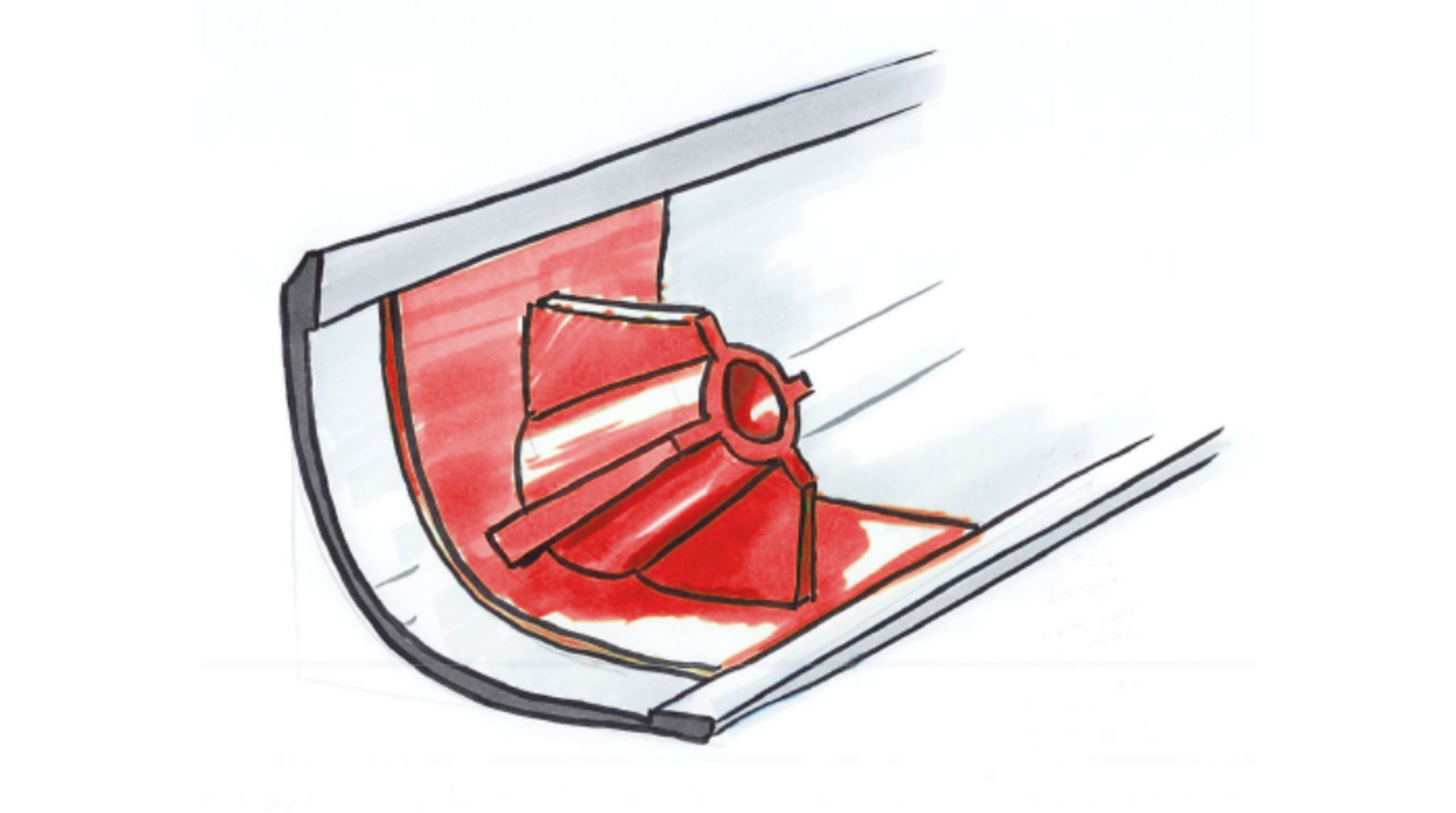

Thanks to the mobility of injection moulding technology, individual functionalisations can be applied locally. The advantages of the new way of thinking of ANYBRID can thus be exploited in a wide range of applications.

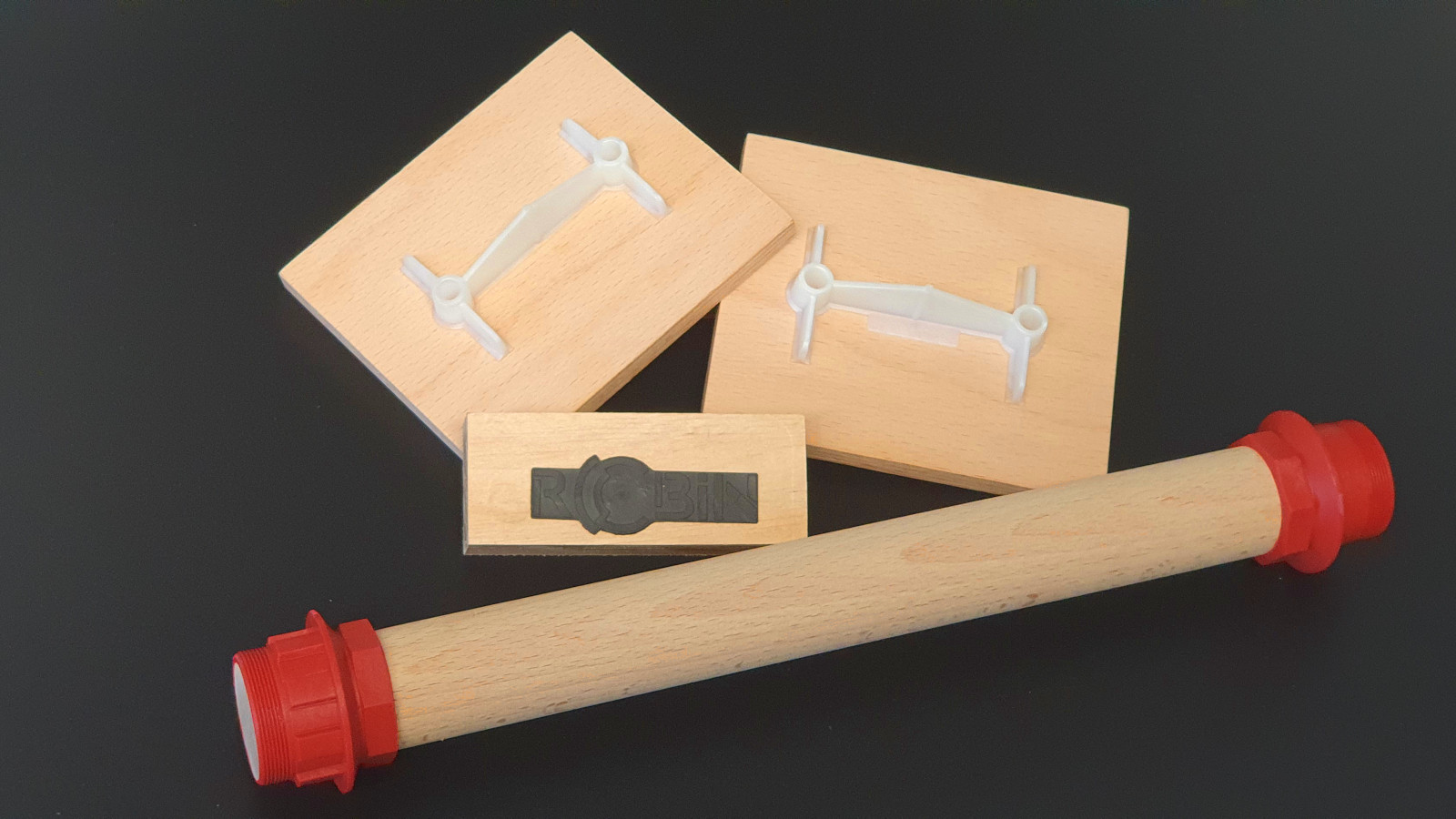

Case Studies

Design.

Benefit from extensive advantages in product design!