Technology.

The biggest challenge in the realisation of manufacturing processes for the production of hybrid components is often the high mould costs and the great effort required for the installation of the necessary plant technology.

With our system, we lower the barrier to enable the rapid use of our injection moulding technology in your production.

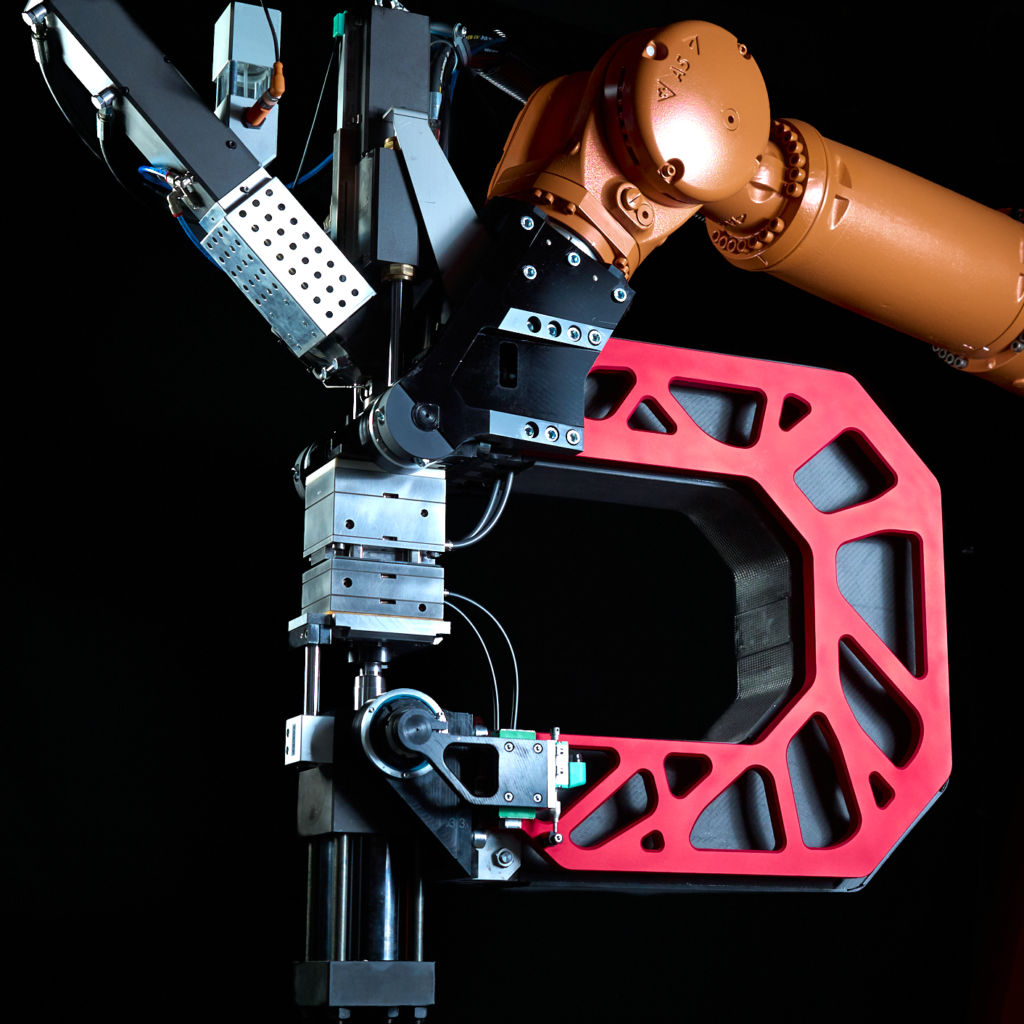

We think beyond the process and bring the machine and the mould to the part.

References.

Out of the press

Composites World: „Robotized System makes overmolding mobile and flexible“

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Awarded with the Pioneer of the Leichtbauwelt 2022

The readers of the news platform Leichtbauwelt voted us the winner of the "Pioneer of the Lightweight Engineering World 2022". ANYBRID won 33.1 percent of the votes by a wide margin.

The injection molding upgrade for high-volume 3D printing

The mobile injection molding "ROBIN" as a supplement to large-volume 3D printing. In this way, currently existing challenges in post-processing can be solved in a particularly elegant way.

Composites World: „Robotized System makes overmolding mobile and flexible“

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Awarded with the Pioneer of the Leichtbauwelt 2022

The readers of the news platform Leichtbauwelt voted us the winner of the "Pioneer of the Lightweight Engineering World 2022". ANYBRID won 33.1 percent of the votes by a wide margin.

Awards

Nominated: Best of Industry Award

We are nominated for the Best of Industry Award from MM Maschinenmarkt in the category plastics technology. Support us with your vote now!

JEC AWARD 2021

ANYBRID is now really getting into its stride and, together with the Institute for Lightweight Engineering and Polymer Technology at the TU Dresden, wins the JEC AWARD 2021 in the "Equipment and Machinery" category.

AVK Innovation Award 2020

The ANYBRID team is delighted to receive the AVK Innovation Award 2020 for the ROBIN technology in the Processes and Procedures category.

Nominated: Best of Industry Award

We are nominated for the Best of Industry Award from MM Maschinenmarkt in the category plastics technology. Support us with your vote now!

JEC AWARD 2021

ANYBRID is now really getting into its stride and, together with the Institute for Lightweight Engineering and Polymer Technology at the TU Dresden, wins the JEC AWARD 2021 in the "Equipment and Machinery" category.