ROBIN in the extrusion line

in cooperation with

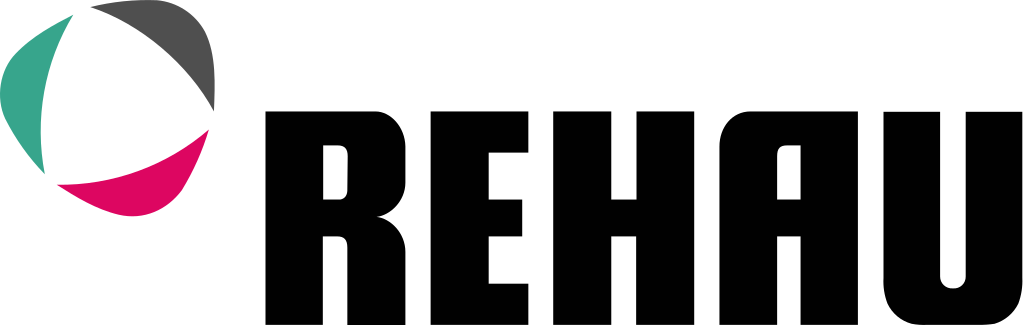

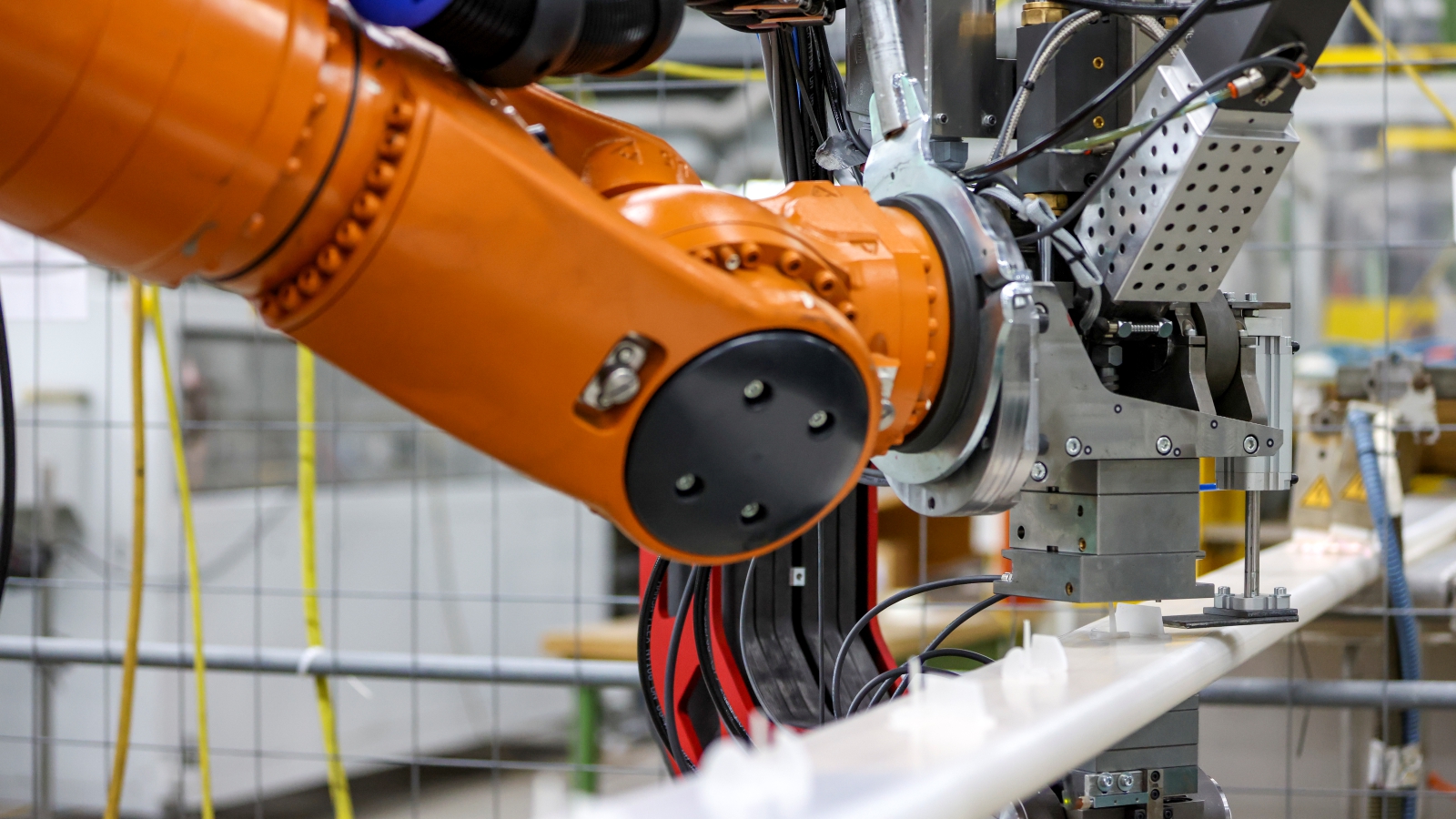

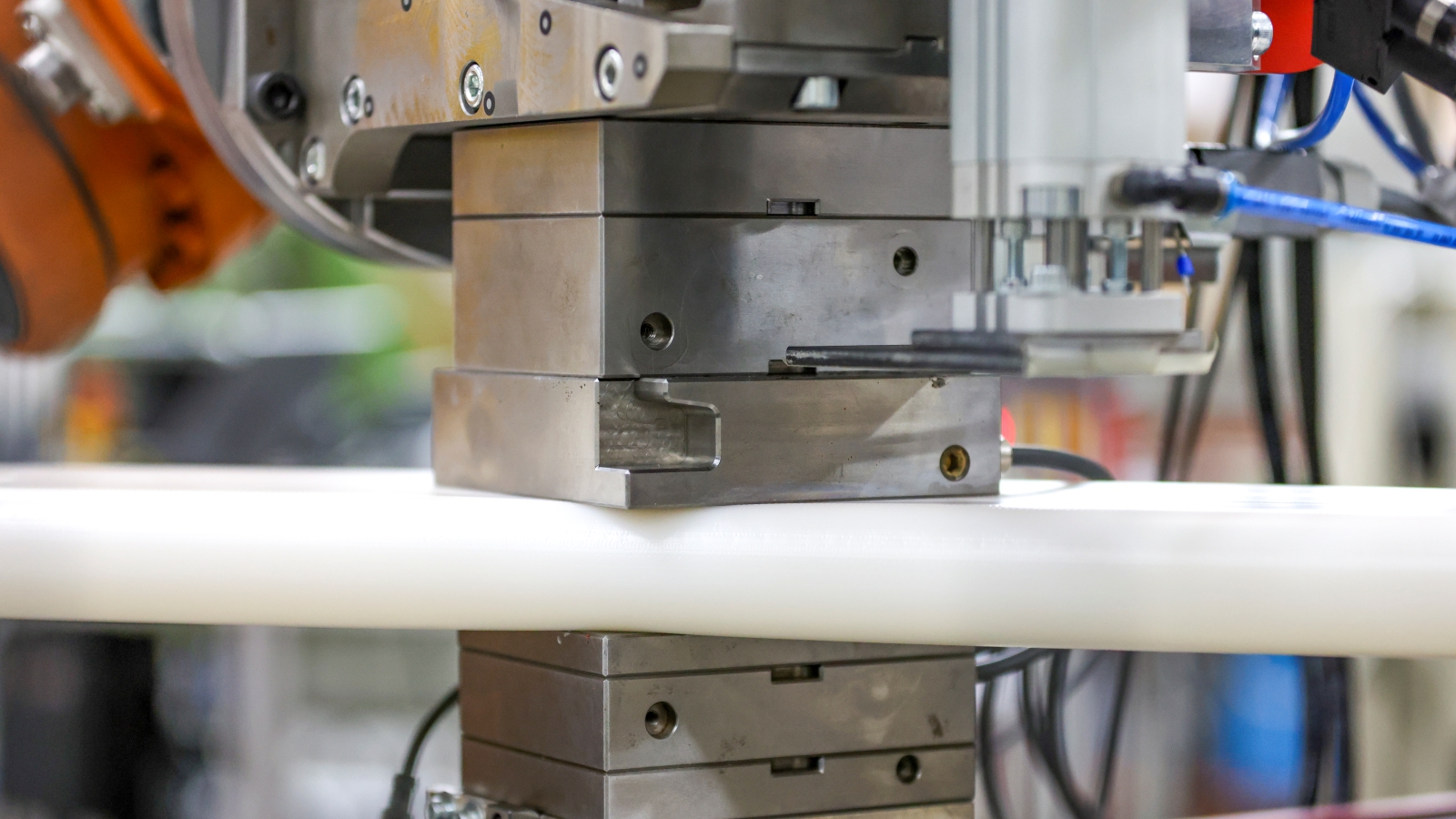

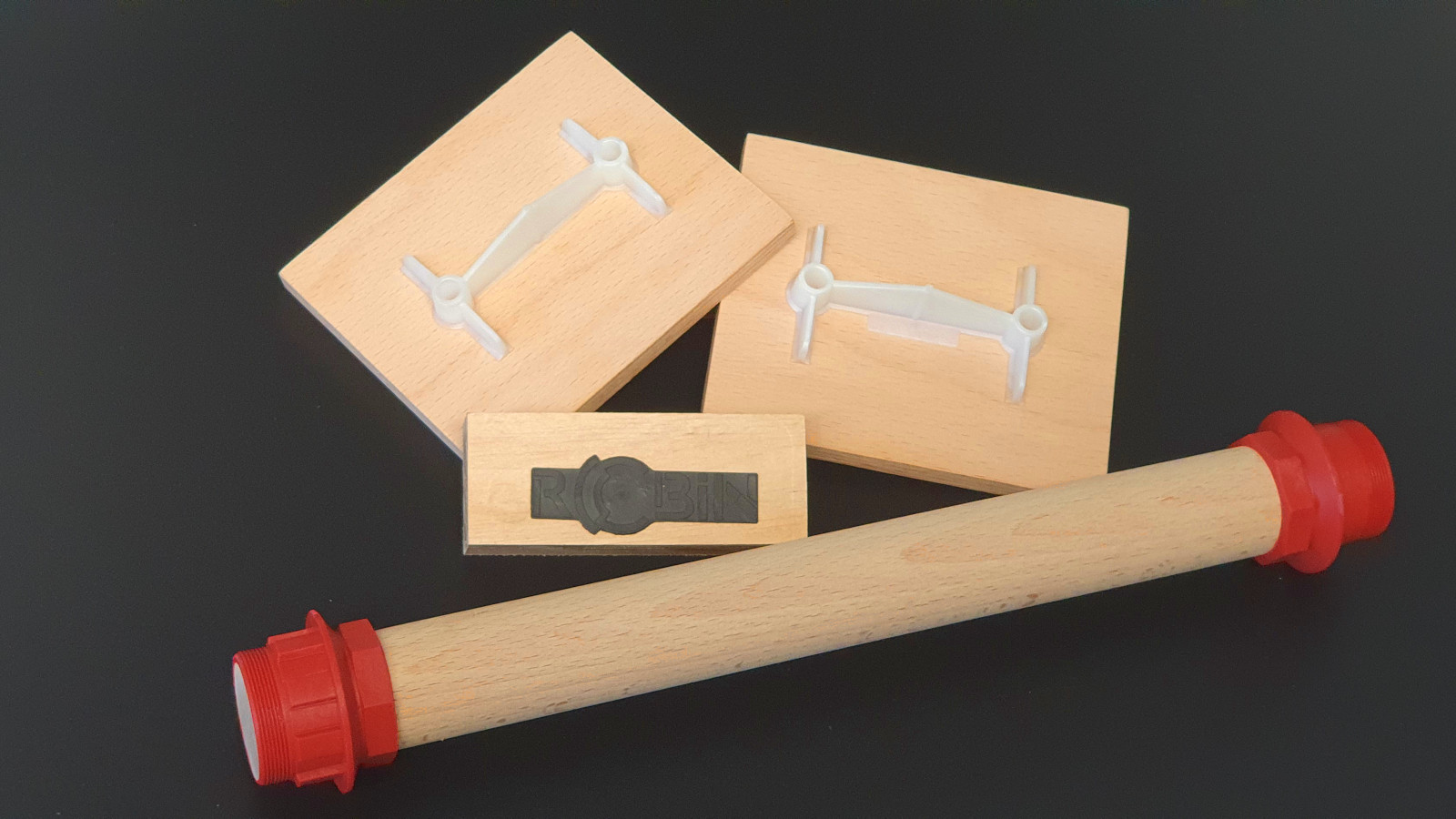

In close cooperation with the Innovation Group of REHAU Industries the ROBIN technology was integrated directly into a profile extrusion line. Functionalisations were applied to an extruded profile at regular intervals.

It is essential to match the line speed of the profile with the cycle and in particular the necessary cooling time of the overmoulded functional element. The feasible process window is determined by the required distance between the functional elements. Furthermore, it has been shown that for different types of plastic such as PE-HD, ASA, ABS, TPE, TPU, PC und PVC good bonding strengths can be achieved both as mono-material systems and in various combinations with each other. The qualification of further materials is the subject of current investigations.

For more information, see the pictures, the process video or the article in Kunststoffe-magazine (issue 02/2022, German and English).