INSERT Functionalisation

in cooperation with

The use of composite materials in structural applications creates specific challenges for joining. The correct load application in fiber-reinforced plastics is essential to fully exploit the potential of these lightweight materials.

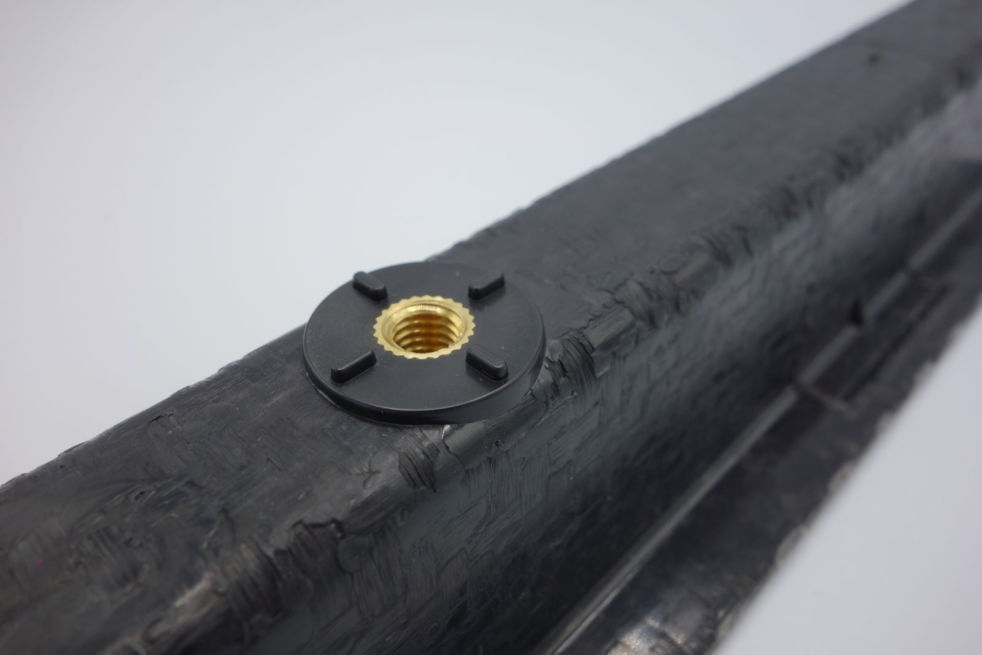

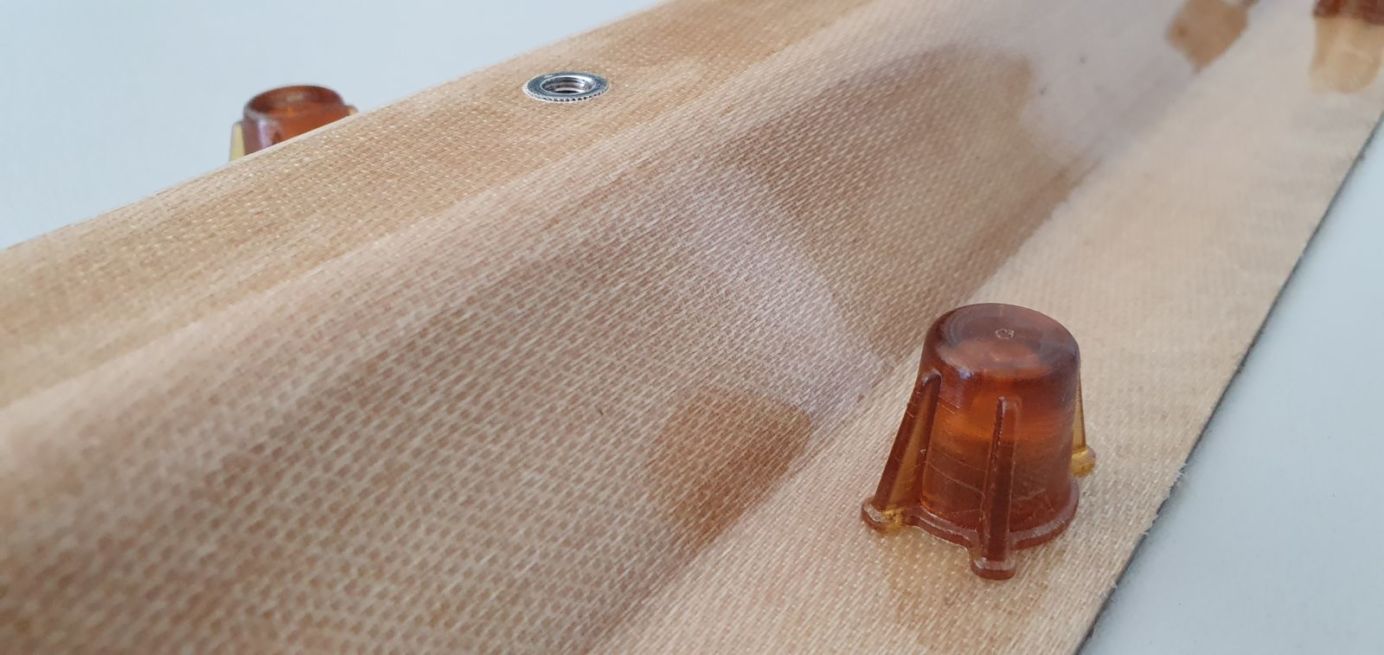

Together with the Innovation Group of REHAU Industries we have consequently developed a material-specific way of adding inserts using mobile injection moulding. A high bonding strength between the composite component and the injection moulding material is particularly important. Both for different Polyamide (PA) based materials and for Polyetherimide (PEI) a high bonding strength could be achieved in extensive investigations. The results of these developments are demonstrated by composite profiles with molded inserts. High-performance components based on aerospace applications have also been implemented using PEI materials.

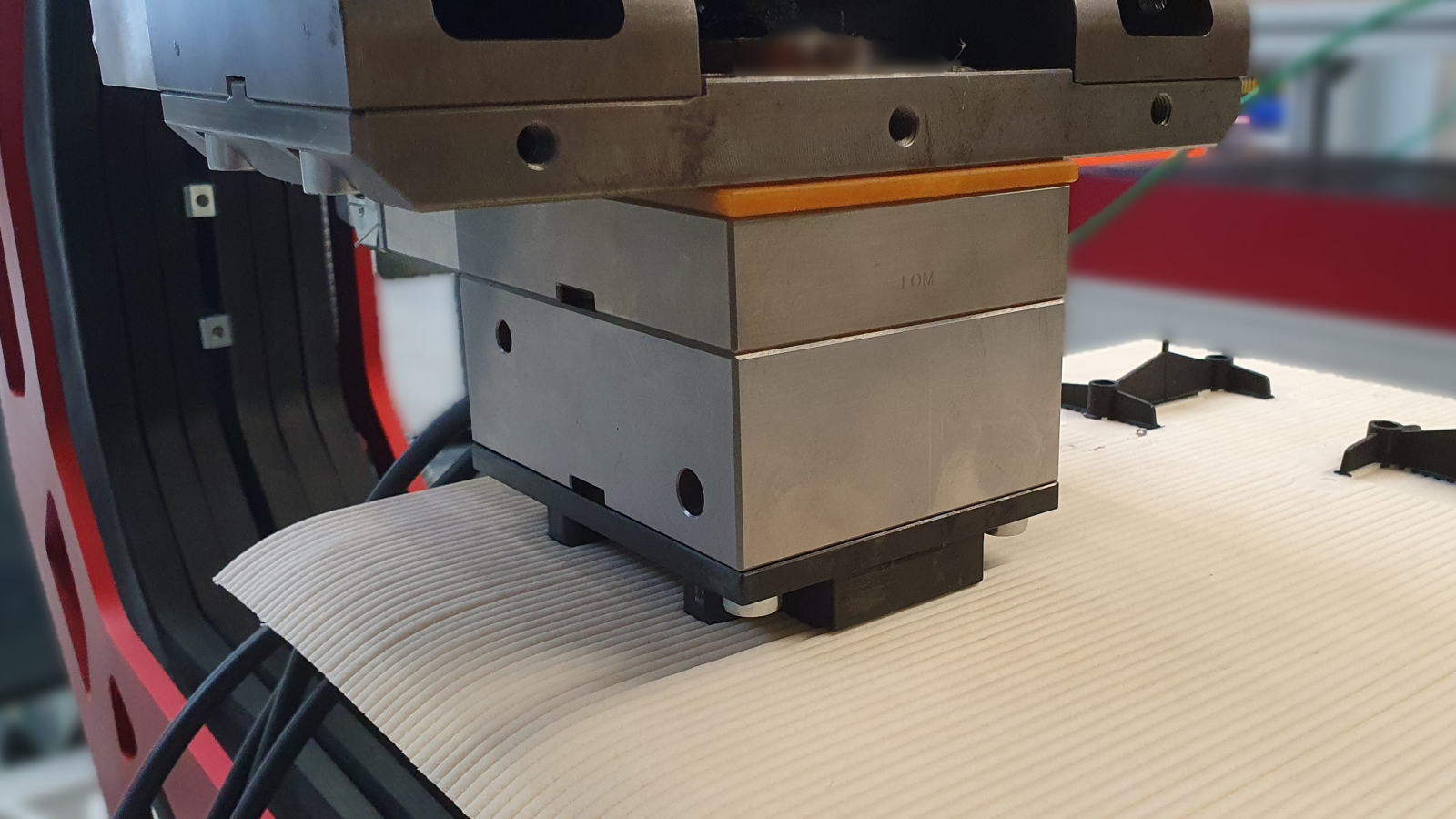

An essential part of the process chain is the production of profiles in continuous manufacturing processes (such as continuous compression moulding or extrusion). In the future, mobile injection moulding will be directly integrated in order to apply the functional elements with the inserts in the production line as required. Offline functionalisation of composite profiles or assemblies can also be flexibly realised with different material combinations and variable insert positions.

Advantages

- Mono-Material-Design

- Integration of the Insertion of Joining Elements in the process line

- Flexible offline functionalisation with different material combinations

- Hohe erreichbare Auszugskräfte

- Integration of additional functionalisations: e.g. sealing and anti-twist resistance

For more inspiration, check out the images:

Special thanks to the support and the supply of materials: