THE FLYING

INJECTION-MOLDING MACHINE

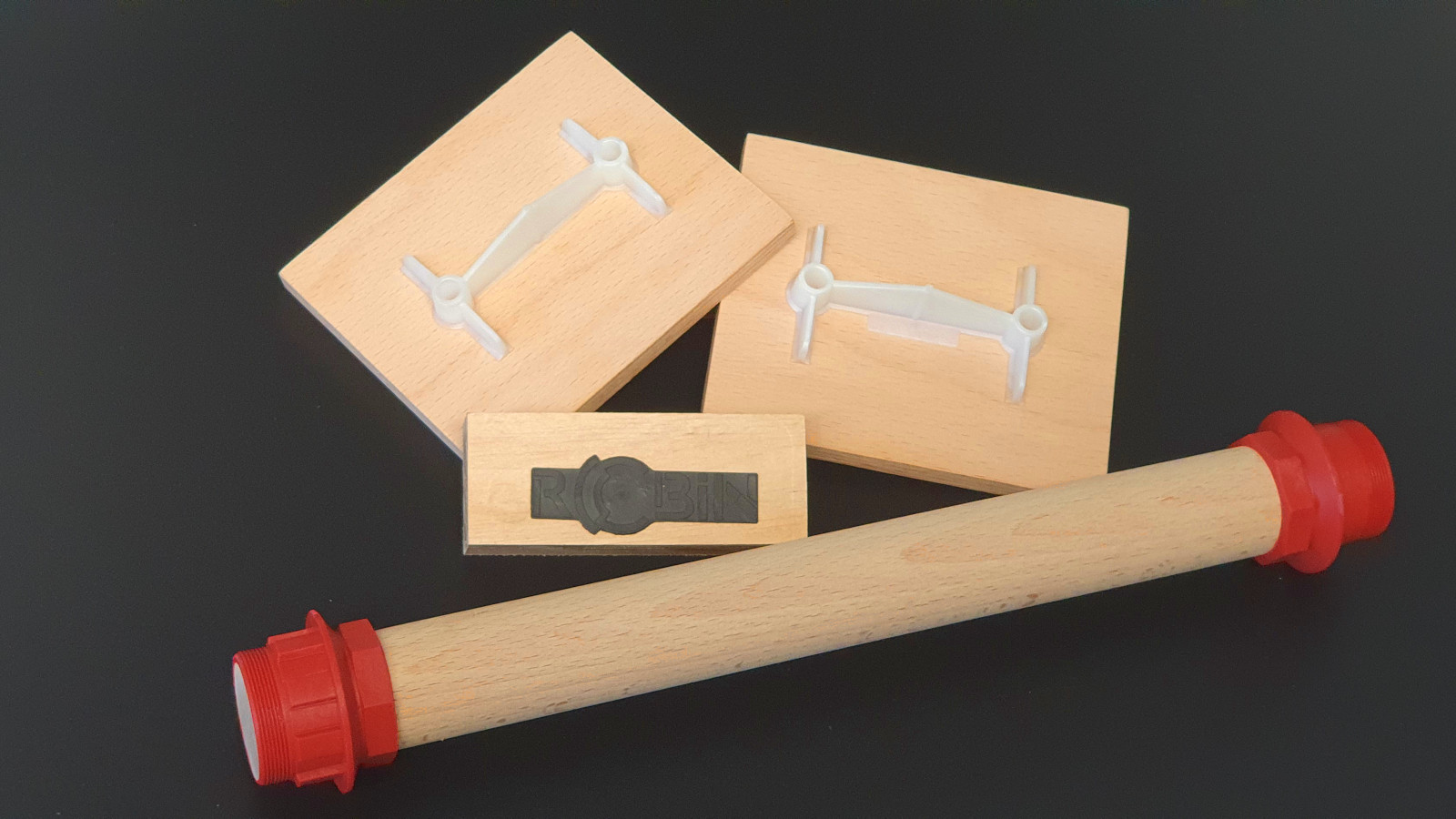

Injection molding meets additive manufacturing!

Our mobile injection molding technology integrates perfectly into your production line and offers the perfect trade-off between flexibility and efficiency.

We integrate injection molding directly into the extrusion line, into automated assembly or into variable robot cells.

Are you curious whether this can be useful in your production?

Together with you, we will find out.

Multiple awards

THE FLYING

INJECTION-MOLDING MACHINE

Spritzgießen trifft additive Fertigung

Our mobile injection molding technology integrates perfectly into your production line and offers the perfect trade-off between flexibility and efficiency.

We integrate injection molding directly into the extrusion line, into automated assembly or into variable robot cells.

Are you curious whether this can be useful in your production?

Together with you, we will find out.