24. January 2023

The injection molding upgrade for high-volume 3D printing

The mobile injection molding "ROBIN" as a supplement to large-volume 3D printing. In this way, currently existing challenges in post-processing can be solved in a particularly elegant way.

Excerpt from the press release:

In recent years, a number of companies have jumped on the train of large-scale 3D printing based on plastic pellets, which is why the applications for realizing technical components are also increasing rapidly. This production technology is known as large-scale additive manufacturing (LSAM). From established injection molding and special machine manufacturers to startups, a variety of different LSAM printers are offered using gantry systems or robotics. These printers are characterized by high output rates of 10 to 30 kg/h and the processing of common thermoplastics. However, the high output rate goes hand in hand with the fact that the detail accuracy of the components, as known from injection molding, for example, has its limits. Currently, the molded parts are often reworked in the milling process, for example, to smooth the characteristic surface of 3D printed structures and to create precisely fitting functional surfaces.

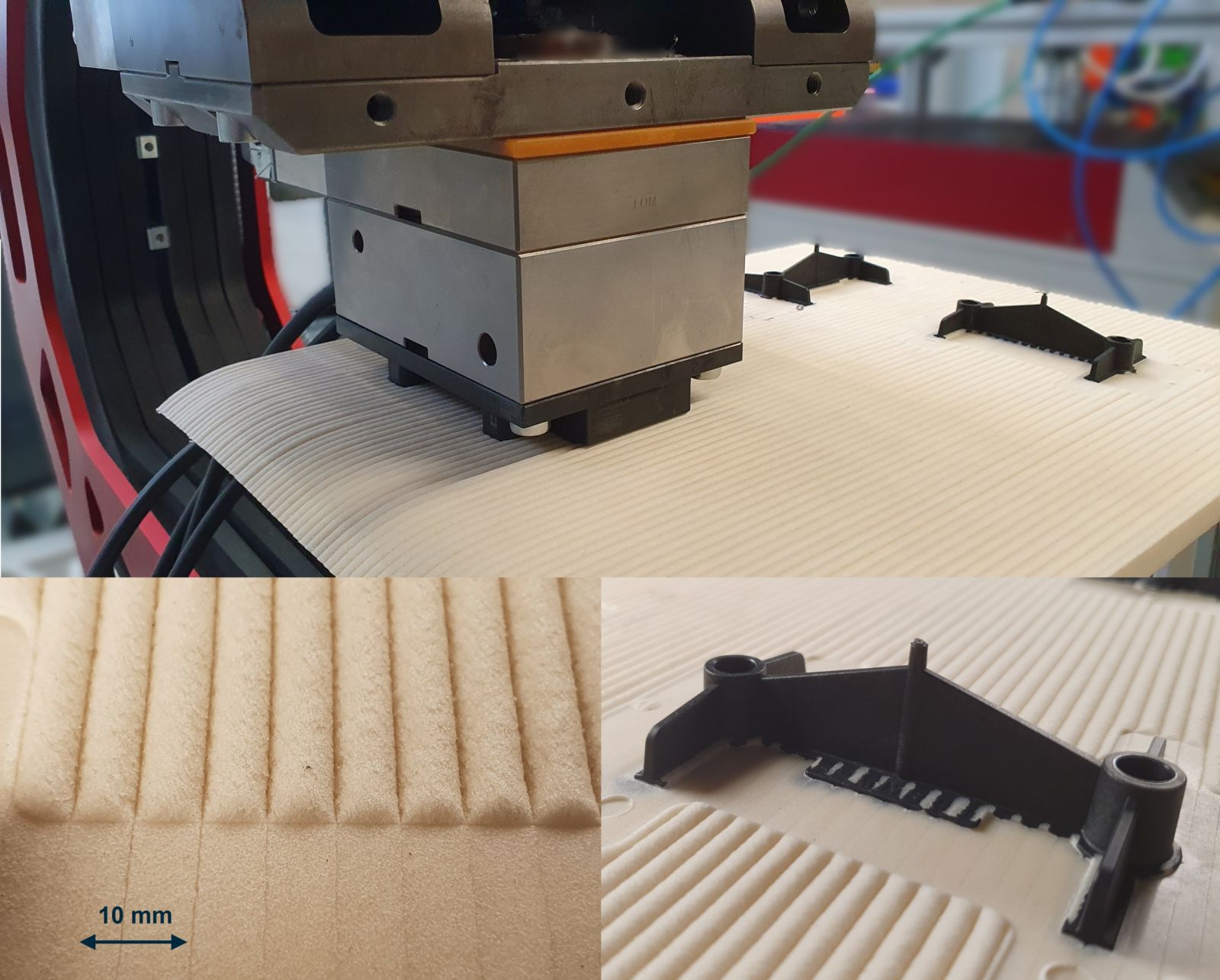

The mobile injection molding "ROBIN" of ANYBRID GmbH now offers a new alternative of process-integrated or downstream functionalization of 3D-printed components. Due to the unique possibility of the ROBIN system to mount it on classical industrial robotics, it is possible to integrate it directly into the LSAM production cell in order to inject functionalizations locally onto the components. In initial trials in cooperation with the Institute for Lightweight Engineering and Polymer Technology at TU Dresden, the proof of concept was successfully carried out. After brief surface heating, additively manufactured plates were locally compacted and formed by applying the clamping force. In this way, the sealing of the mold cavity can be ensured for the subsequent overmolding process.

Voices:

Christian Vogel from ILK: "The degrees of freedom in the design of LSAM components are already high. These can now be significantly multiplied by combining them with mobile injection molding and go well beyond the printing of flower vases that has often been presented to date."

Michael Stegelmann from ANYBRID: "We firmly expect that large-volume 3D printing facilities in the future will be equipped with our mobile injection molding system as standard."

Erschienen über folgende Medien:

- Zeitschrift: Additive Fertigung

- Additive-Fertigung

- Plastverarbeiter

- Industry of Things

- Additive Manufacturing Industry

- Kunststoffe

- Kunststoffe International

The complete press release can be found here!

Overmolding of the 3D printed structures (top); Comparison of the 3D printed and the compacted surface (bottom left); Overmolded rib structure (bottom right).