Technology.

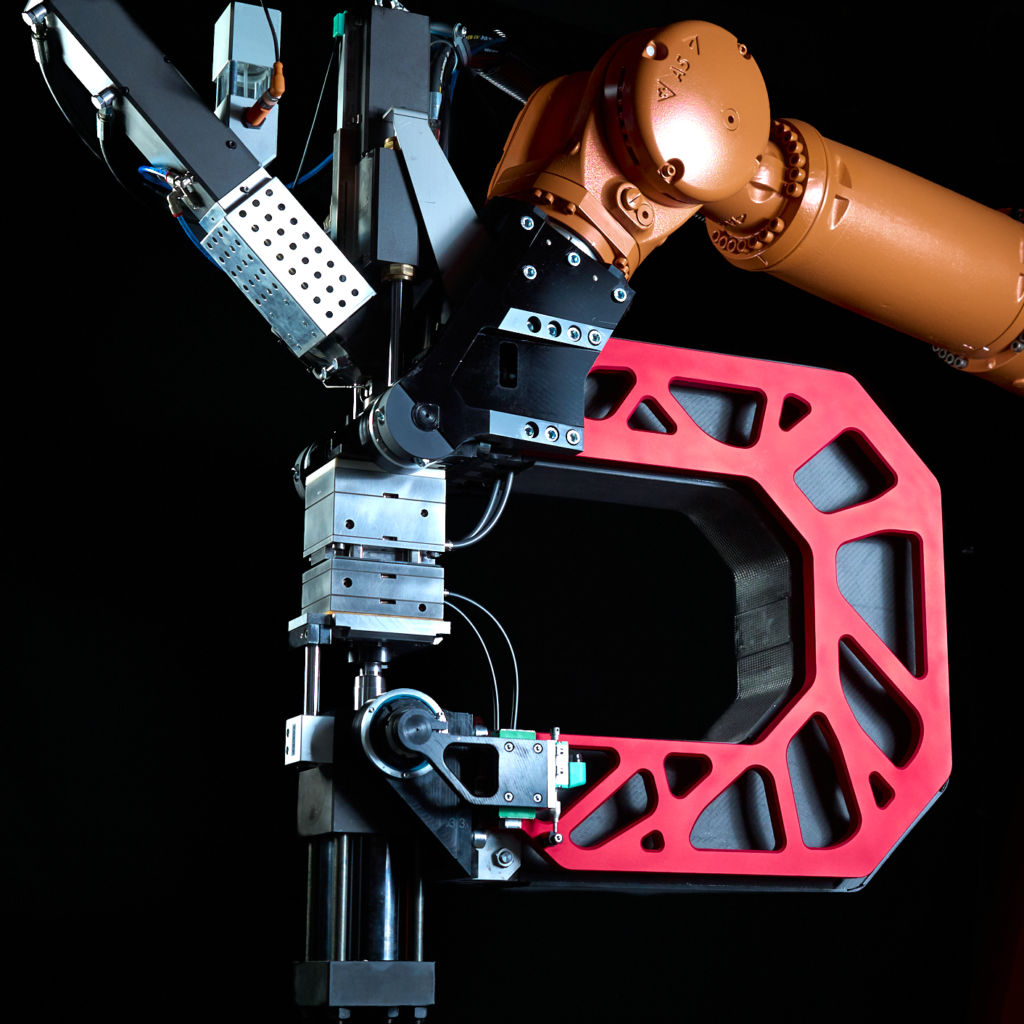

High-Performance Schließsystem

Flexible automation

Compact injection system

Minimalistisches Werkzeug

ADVANTAGES

-

Lightweight and mobile plant technology

-

Integration capability in process lines

-

Variable application of functional elements

-

Wide range of material combinations

-

Option for multiple systems

BENEFITS

-

Savings in process and assembly steps

-

Increased manufacturing flexibility

-

New options in product design

-

Expansion of the product portfolio

-

Easy scalability